PLC-Based Liquid Level And Flow Control Quiz

PLC-Based Liquid Level And Flow Control Quiz offers users an engaging opportunity to test their knowledge on essential concepts and applications in liquid level and flow control systems through 20 diverse questions.

You can download the PDF version of the quiz and the Answer Key. Or build your own interactive quizzes with StudyBlaze.

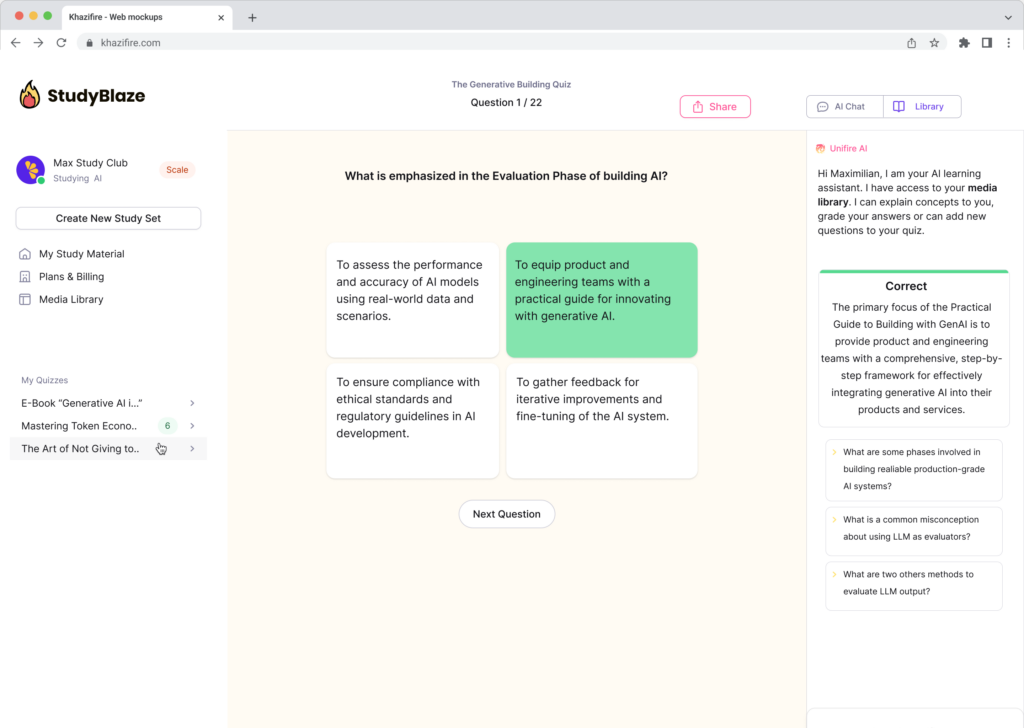

Create interactive quizzes with AI

With StudyBlaze you can create personalised & interactive worksheets like PLC-Based Liquid Level And Flow Control Quiz easily. Start from scratch or upload your course materials.

PLC-Based Liquid Level And Flow Control Quiz – PDF Version and Answer Key

PLC-Based Liquid Level And Flow Control Quiz PDF

Download PLC-Based Liquid Level And Flow Control Quiz PDF, including all questions. No sign up or email required. Or create your own version using StudyBlaze.

PLC-Based Liquid Level And Flow Control Quiz Answer Key PDF

Download PLC-Based Liquid Level And Flow Control Quiz Answer Key PDF, containing only the answers to each quiz questions. No sign up or email required. Or create your own version using StudyBlaze.

PLC-Based Liquid Level And Flow Control Quiz Questions and Answers PDF

Download PLC-Based Liquid Level And Flow Control Quiz Questions and Answers PDF to get all questions and answers, nicely separated – no sign up or email required. Or create your own version using StudyBlaze.

How to use PLC-Based Liquid Level And Flow Control Quiz

The PLC-Based Liquid Level And Flow Control Quiz is designed to assess understanding of key concepts related to Programmable Logic Controllers (PLCs) utilized in managing liquid levels and flow rates in various industrial applications. The quiz consists of a series of questions that cover topics such as the fundamental principles of liquid level measurement, the operation of different types of sensors, the programming logic used in PLCs for controlling pumps and valves, and the safety protocols necessary for effective liquid handling. Upon completion, the quiz automatically grades the responses, providing immediate feedback on the performance. The scoring system offers a clear indication of the correct answers and the areas where further study may be needed, enabling participants to identify their strengths and weaknesses in PLC-based liquid control systems. This streamlined approach not only facilitates learning but also ensures that participants can efficiently gauge their mastery of the subject matter.

Engaging with the PLC-Based Liquid Level And Flow Control Quiz offers a unique opportunity for individuals to deepen their understanding of critical concepts in automation and control systems. Participants can expect to enhance their problem-solving skills while gaining insights into practical applications of PLC technology, which are essential in modern industrial environments. This quiz not only reinforces foundational knowledge but also introduces advanced topics that can lead to improved efficiency and productivity in various processes. Furthermore, by testing their knowledge, participants can identify areas for growth, allowing them to tailor their learning experiences effectively. Ultimately, taking the PLC-Based Liquid Level And Flow Control Quiz empowers individuals to stay competitive in the ever-evolving field of automation and provides them with valuable skills that can be directly applied in their careers.

How to improve after PLC-Based Liquid Level And Flow Control Quiz

Learn additional tips and tricks how to improve after finishing the quiz with our study guide.

To master the topic of PLC-Based Liquid Level and Flow Control, it is essential to understand the basic principles of how Programmable Logic Controllers (PLCs) operate in conjunction with sensors and actuators to manage liquid levels and flow rates in various applications. Start by reviewing the types of sensors commonly used in liquid level detection, such as float switches, capacitive sensors, and ultrasonic sensors. Learn how these sensors provide input signals to the PLC, which processes the data based on predefined logic. Familiarize yourself with the programming logic used in PLCs, including ladder logic diagrams and function block diagrams, as these are critical for developing control strategies. Additionally, pay attention to the different control methods, such as on-off control and PID control, and understand the advantages and disadvantages of each in maintaining desired liquid levels and flow rates.

Incorporate practical examples and case studies to see how PLCs are applied in real-world scenarios. Analyze different control systems, such as those used in water treatment plants, chemical processing, and food and beverage industries, to understand how PLCs help achieve efficient and safe operations. It’s also important to study troubleshooting techniques for common issues that may arise in liquid level and flow control systems, such as sensor failures or actuator malfunctions. By integrating theoretical knowledge with practical applications, students can develop a comprehensive understanding of PLC-based liquid level and flow control systems, enhancing their ability to design, implement, and maintain these systems effectively. Regularly revisiting these concepts and practicing programming exercises will further solidify your understanding and skills in this area.